ОМК VEGA

Premium gas-tight full-strength thread and coupled connection

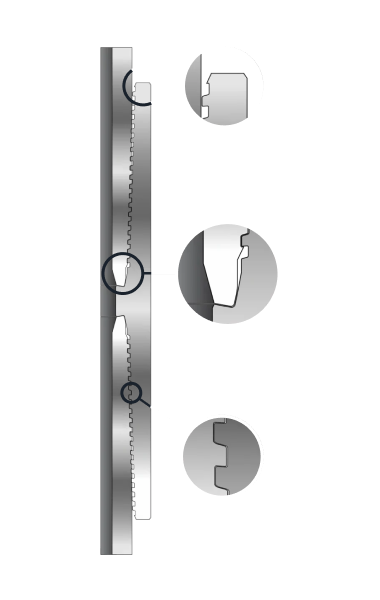

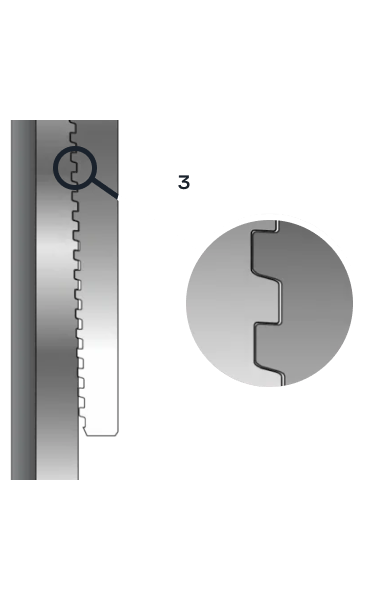

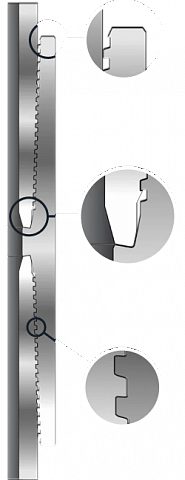

The connection is designed with a special thread hooked profile witha negative angle, a metal-to-metal seal, and full strength that assures that the connection remains gas-tight under a compressive load equal to 100% of pipe body strength.

| Size: | 4 ½ - 13 3⁄8 in |

| Grades: | from K55/J55 to Q125 |

| Tubular Type: | seamless |

| Tensile Efficiency: | 100% |

| Compressive Efficiency: | 100% |

| Turns per inch (thread pitch): | 4 (6,35 mm) |

| Manufactured per: | API 5CT GOST 31446-2017 |

| Size: | 4 ½ - 13 3⁄8 in |

| Grades: | from K55/J55 to Q125 |

| Tubular Type: | seamless |

| Tensile Efficiency: | 100% |

| Compressive Efficiency: | 100% |

| Turns per inch (thread pitch): | 4 (6,35 mm) |

| Manufactured per: | API 5CT GOST 31446-2017 |

Potential Applications

- Oil, gas, and offshore fields

- Vertical, extended reach drilling and horizontal wells

- Construction of long offshore and onshore ERD wells with type -S and -L profiles

- Wells with aggressive H2S and CO2 environments

- Production of heavy crude oil using SAGD

- Casing running and cementing technologies with rotation in a long horizontal wellbore

- Multistage frac operations in long horizontal casing strings

Factors of Improved Reliability

- Special thread hooked profile with a negative angle protects the connection from dissemble when running the strings

- An increased TPI allows for better thread assembly on a rig under field conditions

- The thread connection is of equal strength with a pipe body. Efficiency connection in compresion equals to 100% of the pipe body

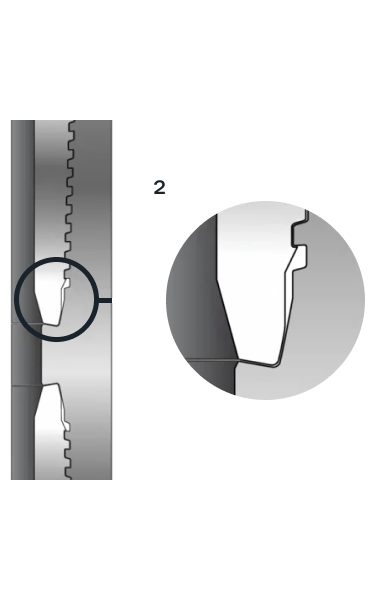

- The gas-tight metal-to-metal seal assembly guarantees leak-proofness at high bending and compression loads

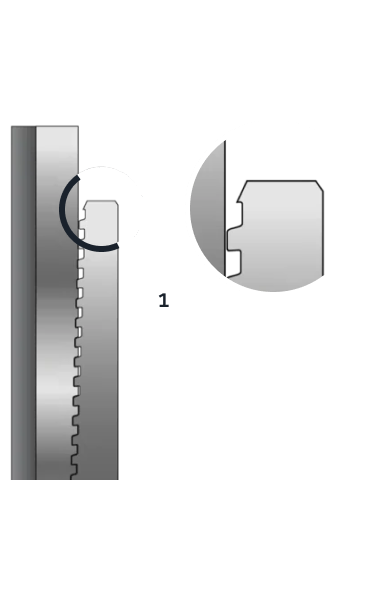

- Additional internal shoulder providing resistance to high torques

- An increased connection ID allows for more flexibility in selection of downhole equipment

- Inspection of thread connection assembly based on specified make-up torques and an assembly diagram

- CLEAN SPACE dope-free technology option

- OMK VEGA design has been verified by successful bench testing per API 5C5:2017 CAL IV level

Receive consultation